Exploring the complex field of wind turbine generators (WTGs) reveals an environment full of difficulties and nuances. It is critical to understand the dangers and hazards related to Maintenance activities when ensuring efficient operation of wind turbines. The following overview covers the complex area where wind energy’s dynamic landscape is shaped by the convergence of natural, operational, and safety issues. The development of wind energy projects depends on handling the risks related to WTG operations, spanning from mechanical weaknesses to unpredictable weather patterns.

Falling from Height

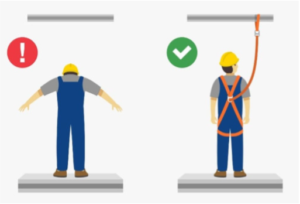

One of the main risks of working on wind turbines is falling, as practically everyone would imagine. There is still a very real risk even with the safety precautions in place and the requirement to wear personal protective equipment whenever working on these enormous turbines.

Even while falls can happen at any time, installing the turbine poses one of the highest risks. Workers must carefully ascend to make sure everything is in its right location because one mistake may spell disaster if they are not securely fastened to the turbine.

However, a common misconception is that falling does not always entail hitting the ground completely. Sliding from a ledge or ladder can still be extremely risky, even with the right harnesses and personal safety equipment. The workers may suffer from whiplash or possibly break bones as a result of the force of the harness system catching them.

Employees should constantly make sure their fall protection gear, including harnesses, is being used correctly to reduce any chance of falling. In order to ensure the safety of any falls that do occur, minimise the slack in the lines as well.

Confined Space activities:

The majority of people don’t even think about restricted spaces as a risk when discussing wind turbine safety. However, the truth is that while working on the wind turbine, employees can be confined in four distinct zones. They are as follows:

Tower: The turbine’s vertical tower is both spacious and constrained. An employee runs the risk of getting trapped or hurt if they have to enter this region to finish a repair or carry out an installation stage.

Nacelle: The turbine’s

Hub: This component, which connects to the nacelle, is a small space where

Blades: In order to maintain or repair the blades, employees may need to enter this region. The blades attach to the hub. This is regarded as a restricted area as well.

These small areas can present a serious risk when working on wind turbines, whether they are being constructed or maintained. But because they are operating such massive machinery, even the staff frequently forget that these are cramped areas. This being said, it could be a good idea to make warning labels that can be applied to each of these four locations using an industrial label printer.

Electricity

Since wind turbines are capable of producing enormous amounts of power, it should come as no surprise that electrocution is a serious risk to consider when considering wind turbine safety. Workers who are directly handling electrical equipment, for instance, must take every precaution to guarantee that electricity generation has ceased.

Encouraging safety can be achieved by implementing a customised version of the lock out tag out system. To do this, turn off the turbine so that the blades are unable to rotate and produce electricity. To prevent the controls from being turned back on while the electrical equipment is being serviced, consider installing a lock of some kind on them.

Fire

The possibility of a fire starting is another risk associated with these turbines. A lightning strike to the turbine, an overload in the electrical components, or friction from improperly oiled moving blades might all cause the fire to start. It could be extremely challenging for a worker on a turbine to escape if a fire breaks out.

Wind turbine fires are a serious “green jobs hazard,” according to OSHA, therefore it’s crucial to be aware of this risk. The safety of those around wind turbines should always come first when working on them. Whenever practicable, it should be possible to provide the workers with a quick fall mechanism (such as parachutes or an emergency drop line).

Mechanical Movements

The last concern to be discussed here is the possibility of being struck by the wind turbine’s moving parts. Despite their size, these turbines produce electricity by rotating smaller

Additionally, if someone is working on the gears or another area, it’s possible that their clothing or equipment will become snagged and drag them in or cause them to lose their equilibrium. It is critical that workers be trained to be aware of all moving elements.

Making note of any places that have moving parts is one method to reduce this danger. For instance, using floor marking tape like this one. is one simple method to accomplish this. When implemented correctly, it will notify workers of potentially moving parts even when they are not moving.