The term “Balance of Plant” points to the numerous supporting and auxiliary components of a power plant system that are necessary to create energy. BoP systems offer the necessary assistance to keep the plant functioning smoothly. Inverters, transformers, switchgear, circuit breakers, and other balance of plant components are vital, as are turbines, power generators, and other major power producing equipment. Both electrical and mechanical elements make up a BoP power plant system. Let’s look at the Electrical BoP more in depth.

Types of Balance of Plant

Electrical Work

Civil Work

Electrical Works

Unit Substation

Compact Substation

Transmission Line

Pooling Substation

Grid Substation

Earth Pits

SCADA

1 . Substation Electricals

The electrical components contained at the substation are mostly used to help with the windfarm’s operational characteristics. Switchgear, power protection systems, and the electric metre are commonly included in this category. A transformer may be included in the substation components to allow for power output step up or down. The size of these pieces is determined by the capacity of the windfarm

Once the project capacity is decided the PSS (Pooling Substation), USS (Unit Substation), 33kV Collector network and EHV (Extra High Voltage) Line design will take place suitably.

The standard voltage ratings of PSS are designed as 220kV/33kV, 132kV/33kV, 110kV/33kV and 66kV/33kV.

2 . Unit Substation (USS)

A close-coupled assembly containing enclosed main high-voltage equipment, a three-phase power transformer, and enclosed secondary medium-voltage equipment is known as a unit substation

The following are the common electrical ratings for USS

- 33kV/690V/415V-Primary/Secondary/Tertiary

- 22kV/690V/415V-Primary/Secondary/Tertiary

- 11kV/690V/415V-Primary/Secondary/Tertiary

3 . Compact Substation(CSS)

A Compact Secondary Substation (CSS) is a type-tested and arc-tested installation that includes a switchgear enclosure, distribution transformers, low voltage (LV) switchboards, connectors, and ancillary equipment for supplying LV energy from MV systems.

4 . Transmission Line

- Bridge to substation and Grid

- Connecting to Substation

The wind farm substation receives the power generated by each turbine. This is accomplished by the use of a medium-voltage collector network (Overhead Line) that connects each turbine to the substation (11-36kV). Overhead and subterranean trenched cabling can be used for connectivity, however overhead lines are the most prevalent. The entire cable length is determined by the distance between the turbines and the substation, as well as the network structure. The length of overhead wire per turbine is around 1.5 to 2.0 kilometers as a rule of thumb.

5 . Connecting to Grid

- This connects the wind farm substation or Pooling Substation to the closest distribution or transmission line. It can be underground but overhead cabling is the most common.

- Although the underground option is mostly preferred due to its lack of visual impact, the overhead option is more economic. The length of the line depends on the distance from the windfarm substation to the point of connection on the main grid. The cable characteristics will depend on the total wind farm rated power and the transmission voltage on the downstream of the wind farm substation.

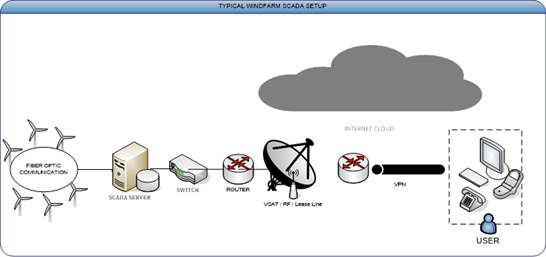

6 . SCADA

- Operational data from turbines.

- Alarms and warnings.

- Start and stop of all turbines.

- Reset turbine trip counters, minimum and maximum temperatures.

- Hours and production counters for individual turbines.