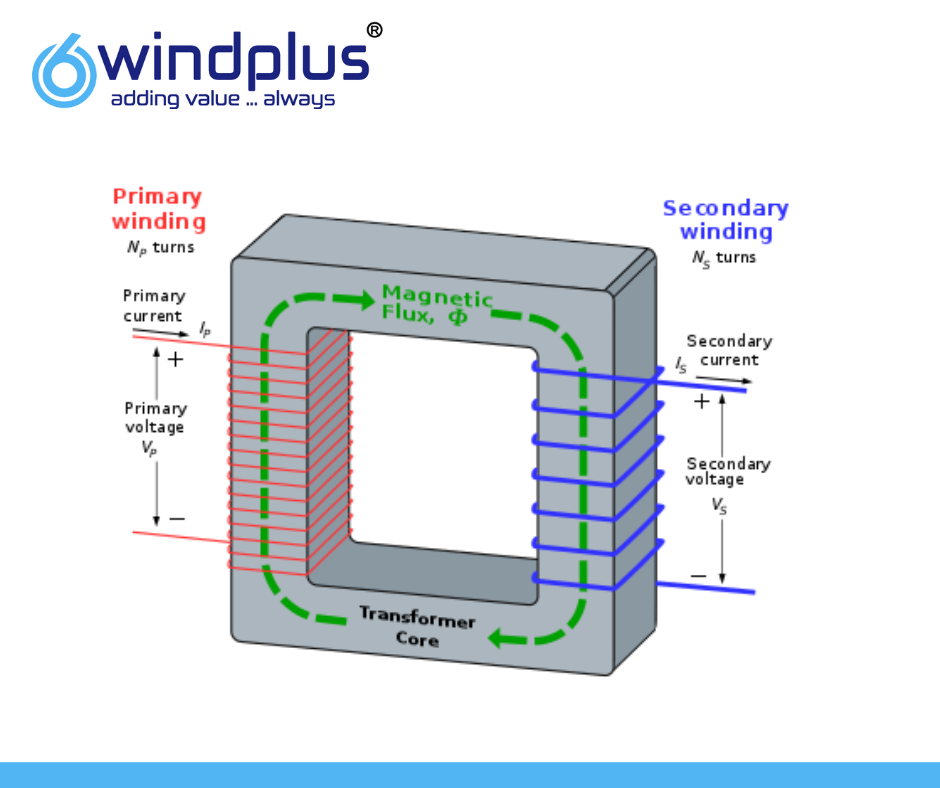

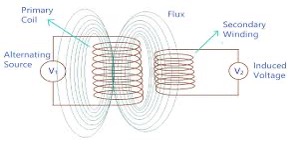

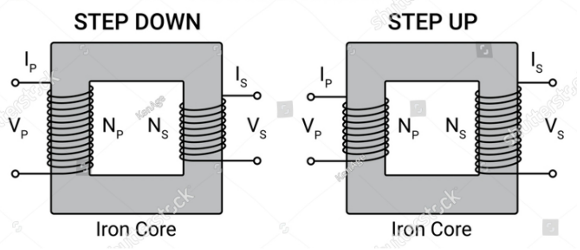

A transformer is a static device that works on the principle of Faraday’s law of electromagnetic induction. A power transformer converts the voltage level of one electrical circuit to another voltage level while transferring the power in the power system network without changing its frequency (Pic.1).

Transformer works on the principle of mutual induction which means that when there is an alternating current flowing in a primary winding of the transformer, the magnetic flux is induced in the core in proportion to the amount of the current flowing through the primary winding. This produces a varying voltage in the secondary winding of the transformer depending on the number of coils in the secondary winding. (Pic.1)

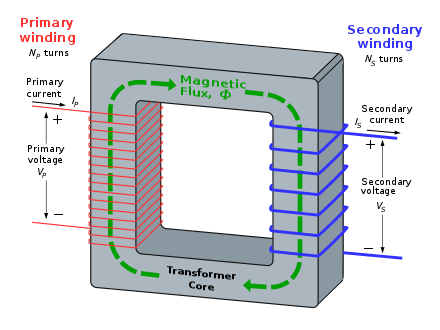

A power transformer has two windings that are magnetically coupled through a core. The number of turns in each winding affects the voltage ratio between the primary and secondary windings. Generally, all electrical machineries work on two principles, namely the principle of self-induction and mutual induction. (Pic.2a & 2b).

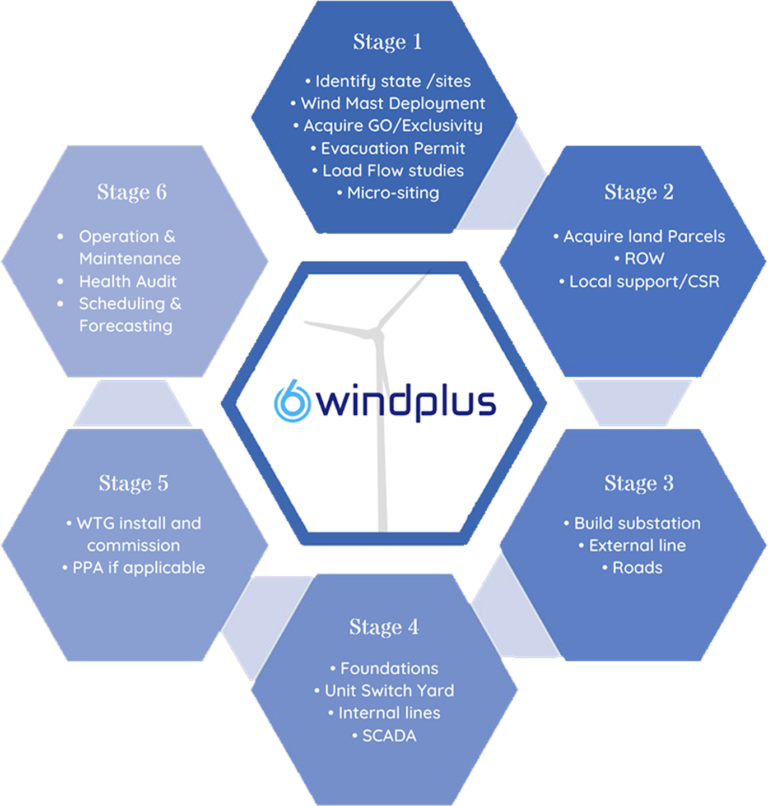

Transformer types can be classify based on below and used as per industrial application requirement with low loss transmission & utilization.

- Based on core construction

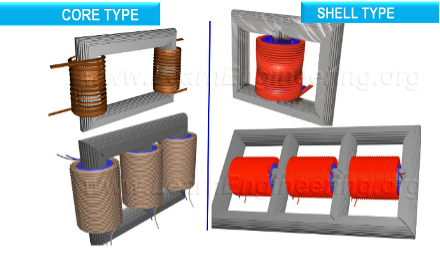

- Core type (‘E I’).

- Shell type ((‘L ‘L)

Core type and shell type transformers differs in their core shapes and winding arrangements. The rectangular core of a core-type transformer has two vertical limbs and a horizontal yoke. The windings are cylindrical and are placed on both limbs (Pic.3)

A shell-type transformer is having a central limb and two outer limbs that form a shell around the windings. The windings are inserted on central limbs and have multiple layers.

- Based on voltage conversion

- Step Up Transformer

- Step Down Transformer

Step-up and step-down transformers are used to increase or decrease the voltage level of an AC supply. Compared to the primary winding, the secondary winding of a step-up transformer has more turns, whereas the secondary winding of a step-down transformer has less turns.(Pic.4)

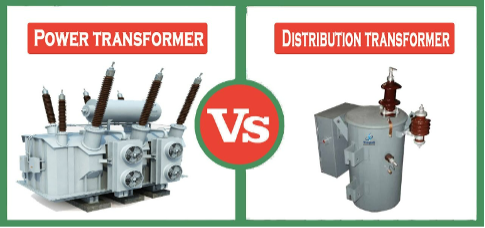

- Based on its purpose - Distribution and power transformers

A distribution transformer is used to step down the voltage for distribution to domestic or commercial users It operates most of the time at full load or nearly to full load and has resilient voltage regulation. A power transformer is used to step up or step down the voltage for transmission between generating stations and substations (Pic.5).

Also, there are single and three-phase types classified into distribution and power transformer types.

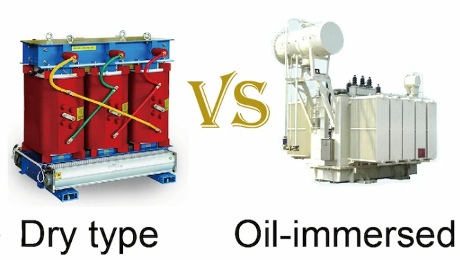

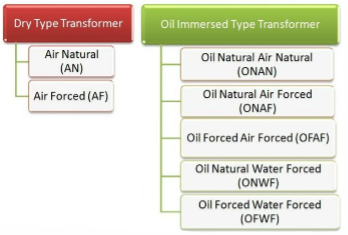

- Based on the insulation used - Oil-cooled and dry-type transformers:

These transformers differ in their cooling methods. Mineral oil is used as a cooling medium for oil-cooled transformers, which flows through radiators or heat exchangers. Air that circulates through vents or fans are used as the cooling medium for dry-type transformers. (In below table its given type of cooling for the transformer-Pic.6a & 6b)

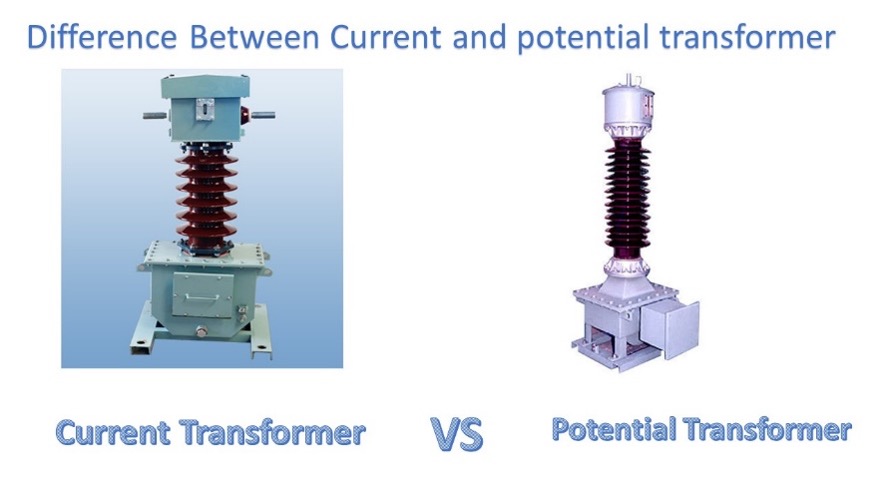

- Instrument transformers

These transformers are used to measure high voltages and currents in a circuit. These types included current transformers (CT) and potential transformers (PT). Also, this type of transformer is used for the protection of the system and to avoid fire hazards during the failure of circuit instruments (Pic.7).

- Difference between Units for Killo Volt Ampere & Killo watts

The transformer is static device and hence no rotating action inside transformer. So, there will not be rotational losses in transformer.

Iron losses and copper losses only be present during operation and due to non-available of additional losses, its phase angle between current and voltage also will not get change between input/ output power. Its power factor is self-governing of the losses.

So, output power -V*I =KVA.

Also, KVA is the unit of apparent power, Transformer is designed without considering the specify load to being connected. It can be connected with any kind of load.

So, transformer rating called in KVA.

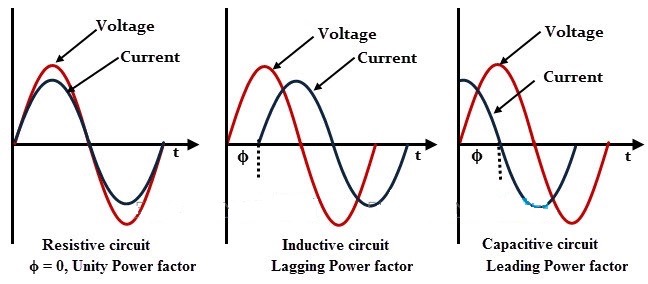

Electrical motors are rotational equipment’s, Since its converting electrical energy to mechanical energy. Due to rotating of machinery’s fraction losses will be occur.

The power factor is fully depending on machine losses. Since phase angle between current and voltage will get change due to load of machine. So, due to variation in load (as inductive load); its power factor also will get change in results of high heating loss

So, the output power = V*I*CosΦ

Below curve explaining about phase angle difference for power factor (Pic .8)

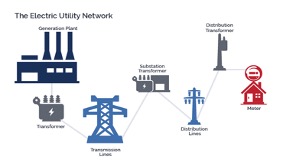

Role of Power Transformer for utilization

Power transformers are one of the key components in power networks. Transformer’s main application is to step up / step down as per domestic / industrial requirements.

The service availability and durability of a transformer are the most important factors in electrical grid to sustain the reliability and transmit the power to customer from Generating station.

In addition, the overall cost of the transmission line over a long period of time is significantly affected by the transformer’s reliability and productivity.

Power transformers are used to reduce the power loss caused by ohmic heating due to high current in transmission line. The distribution is the final stage in delivery of power.

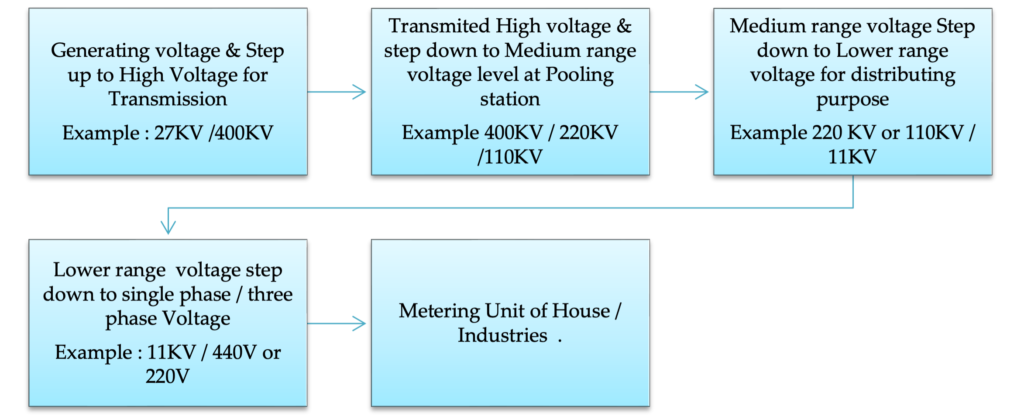

The flow from power generation to consumption of the generated power is indicated in the below picture. (Pic.9a & 9b).